Traditional knee replacements often fail in younger patients due to implant loosening and poor long-term fixation from surgical cement. These failures result in costly and painful revision surgeries, slower recovery, and poor patient outcomes. OSSTEC addresses this challenge by developing cementless 3D-printed partial knee implants that promote natural bone growth, leading to better fixation, durability, and faster recovery.

The London-based medtech startup has secured £2.5M in funding, led by specialist UK-based DeepTech VC Empirical Ventures, to support the commercial launch of its cementless partial knee implant. This follows a £1.2 million seed round in March 2023, with participation from Oxford Investment Opportunity Network (OION), Science Angel Syndicate, Embryo Ventures, Parkwalk Advisors, and SFC Capital. According to Dealroom, OSSTEC’s total funding now exceeds £3 million, including non-dilutive grants and innovation awards.

Related: NeuroOne prices an $8M common stock offering

Max Munford, PhD, CEO and Founder of OSSTEC, said: “This funding marks a pivotal moment for OSSTEC, enabling us to bring our groundbreaking technology to market with our team of surgeons and engage in strategic collaborations to improve patient outcomes. We’re at the exciting intersection of innovative technology, delivering value for surgeons and patients and high-growth markets—all combined to help more people stay active and pain-free for longer. We’re excited to take the next steps in scaling our impact and making a meaningful difference in patients’ lives and the wider healthcare ecosystem.”

Founded in May 2021 by Maxwell Munford, Jonathan Jeffers and Alex Liddle, OSSTEC is a London-based startup built on a decade of Imperial College London research. The team unites world-leading surgeons, experienced engineers, and seasoned founders, combining technical expertise with market knowledge gained through years in medical devices.

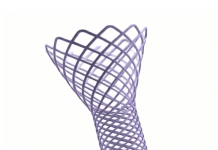

OSSTEC is developing surgeon-led technology to enhance patient outcomes, operating efficiency, and healthcare costs. The company has created patented 3D-printing technology miming cartilage articulating surfaces and bone-fixing structures. Their advanced manufacturing process allows precise customisation of implants to match individual patient anatomy. This is especially valuable for younger patients who need tailored solutions due to their higher activity levels and increased risk of implant failure with conventional methods.

The technology promises to transform orthopedics by significantly reducing implant failure risks and complications, helping patients maintain active, pain-free lives. This benefits healthcare providers through improved efficiency, reduced treatment costs, and increased patient throughput. OSSTEC’s implants integrate seamlessly with robotic-assisted surgical systems, enhancing precision and reducing outcome variability.

This latest funding will help OSSTEC launch in the market and expand its impact with strategic medical partners.

The startup addresses a major issue in orthopedics. Out of 1.3 million knee replacements performed globally each year, approximately 450,000 involve younger patients who are at a greater risk of implant failure. According to OSSTEC, nearly 35% of these younger patients require revision surgery, which can be both expensive and painful. OSSTEC’s implant enhances natural bone growth by avoiding surgical cement, thus improving long-term fixation and lowering the risks tied to conventional cemented implants techniques.

While established companies like Zimmer Biomet, Smith+Nephew, and Stryker offer cementless implants, OSSTEC stands out through its advanced additive manufacturing process. This technology replicates both bone-fixing structures and cartilage articulating surfaces, enabling more natural performance and better body integration.

Unlike competitors’ traditional subtractive manufacturing methods that restrict design complexity, OSSTEC’s additive approach creates intricate lattice structures mimicking natural bone porosity gradients (80–90% at bone interfaces vs. 50–60% internally). This reduces stress concentrations that might cause peri-implant fractures while enhancing post-surgery stability.

Other companies like Conformis are exploring custom-fit implants through 3D printing, while Materialise and Exactech provide digital planning and surgical guides.

“OSSTEC’s 3D printing technology allows efficient manufacturing whilst eliminating mechanisms of failure seen in previous cementless knee replacements,” said Dr Alex Liddle, the company’s Chief Medical Officer and practising orthopaedic surgeon. “This represents an exciting new development in orthopaedics that promises improved fixation and reduced risks, providing value for patients, surgeons and the wider healthcare system.”

Johnathan Matlock, General Partner and co-founder at Empirical Ventures, said: “OSSTEC is an excellent example of how scientific discovery can be transformed into real-world impact. The company has huge potential to completely reform best practices in this field of healthcare, with an impressive team of scientists pushing the boundaries of engineering and medical research. In backing OSSTEC, we continue to drive forward Empirical Ventures’ own mission of empowering the next generation of innovators to turn their research into impactful solutions.”