3D printing is a revolutionary technology that is starting to transform the production of medical device coatings, offering greater possibilities for coverage of unconventional geometries and shapes. We speak to experts at Formacoat to find out how the company is incorporating 3D printing in its application of coatings for medical devices.

3D printing is often described as technology capable of transforming industries of the future, yet its uses in medical devices are already radically upgrading the application of coatings and streamlining production to get products to the market more quickly.

The ability of 3D printing to increase structural strength while reducing the quantity of materials required is of considerable appeal, offering stronger medical devices at lighter weights.

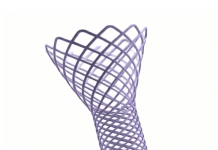

While still in the relatively early stages as a technology, 3D printing is displaying proven capabilities in the application of medical device coatings, easily covering complex geometries of new and existing devices.

One company that has been using the technology is Minnesota-based coatings specialists, Formacoat. Always prepared to push the envelope, notably in its highly innovative R&D team, Formacoat has routinely used experiments as a cornerstone of its operations to accelerate innovations and develop new solutions for medical device coatings.

Jesse Manley, program manager and senior R&D engineer at Formacoat, admits he initially began using a 3D printer outside of work to understand the technology, but the countless possibilities for applications within medical device coatings soon became apparent.

“We have the ability to be like a miniature factory for prototypes or even pilots. And eventually, after validation, manufacturing parts. So, it helps us be pretty agile,” says Manley.

“We don’t have to rely on a lot of other factors. And the cost of that portion of vertical integration is basically purchasing raw material in the form of resins or powders or spools of filament, which is relatively inexpensive compared to lead times and uncertainties around that, amid delays in development.”

The growing uses of 3D printing in coatings for medical devices

The medical device industry has only just started to scratch below beneath the surface of the potential for 3D printing. Flexible 3D printable materials that are biocompatible could transform medical device performance in the not-too-distant future.

However, it is already possible to save substantial time in medical device development through 3D printing by producing complex or unconventional shapes for fixtures that could take a machinist a few weeks or may not even be possible.

“The technology is versatile. If you handed certain plans to a machinist, they’d hand it back to you and say: ‘This is an absolute nightmare’. But I can take that and put that into a 3D printer and within anywhere from an hour to six, I can have a brand-new part fixture ready to go,” explains Riley Bretting, manufacturing engineer at Formacoat. “If I were to get this sent to a machinist, it could take a week to a month depending on the lead time of the machinists that we’re going to. The agility and the versatility are just mind-blowing with this technology and continue to grow year by year.”

Then there is the added strength and versatility that 3D printing offers for devices through the finely layered structures composed of precisely formulated materials. “We have even started using a nylon that is biocompatible. As opposed to the previous biocompatible resin that we were using, this new one has immensely expanded capabilities based on mechanical properties,” Bretting adds. “We used to only be able to create fixtures that were brittle, but they were biocompatible. And now we have parts that are even getting into flexible and even more rigid fixtures as well.”

RELATED: Hybrid behavioral healthcare company Octave scores $52M

Bretting speaks about the significant upgrade that 3D printing offers for medical implants to repair bones, for example, moving away from the traditional screws, nails, and plates to new shapes and lighter, more robust structures.

“3D printing allows us to go from more just standardized tooling and our standardized coating processes to be able to expand this field into having every device that we coat or everything that we do with our coating processes can now be streamlined to be specified exactly to an individual part,” he comments.

“We have just this immensely powerful design capability with the 3D printers that we can create specific fixturing for a specific part. But it’s not going to cost us months of work because we can have this printed overnight. And it can have design features that would be impossible to machine out of metal.”

Ensuring compliance with regulations for 3D printers

Yet for all the potential of 3D printing and its multitude of uses, some obstacles must be overcome regarding regulations and traceability. As with any new technology, it can develop far more quickly than the regulations can. And in a highly regulated industry such as medical devices, compliance with regulations is critical in getting products to market.

What helps provide some guidance is that Manley noticed a crossover between 3D printing and coatings. “3D printing can be a physical process, but some 3D printers are a chemical process where they involve cross-linking and things like that, which is very akin to when we put a coating on a device,” he explains.

“So, you have some raw components, you have a process and then eventually you have a cleaning procedure and a curing procedure. If you treat these similarly to how we regulate and validate coating procedures then they have a lot of similarities.”

To address these issues, Formacoat has been seeking guidance on regulations from carefully selected vendors in the 3D printing field.

“There is a lot of mystery around how to regulate and control these kinds of processes because this is kind of unique,” adds Manley. “We work with certain 3D printing vendors. Because they can help support this kind of regulatory traceability pathway, which is really where we’re pushing. We have a requirement of traceability through regulations, and that makes our application of 3D printing a little unique as we need a little extra with it.

“Each coating has its own batch number for how it’s treated and formulated. Our team records all raw materials, all times and dates, all the care conditions, even solvent lot numbers, everything, you name it. There’s still a lot of ambiguity around it, but these are some good problems to tackle.”